HAVSPRO

The Leading Vibration Monitoring and Measurement Solution

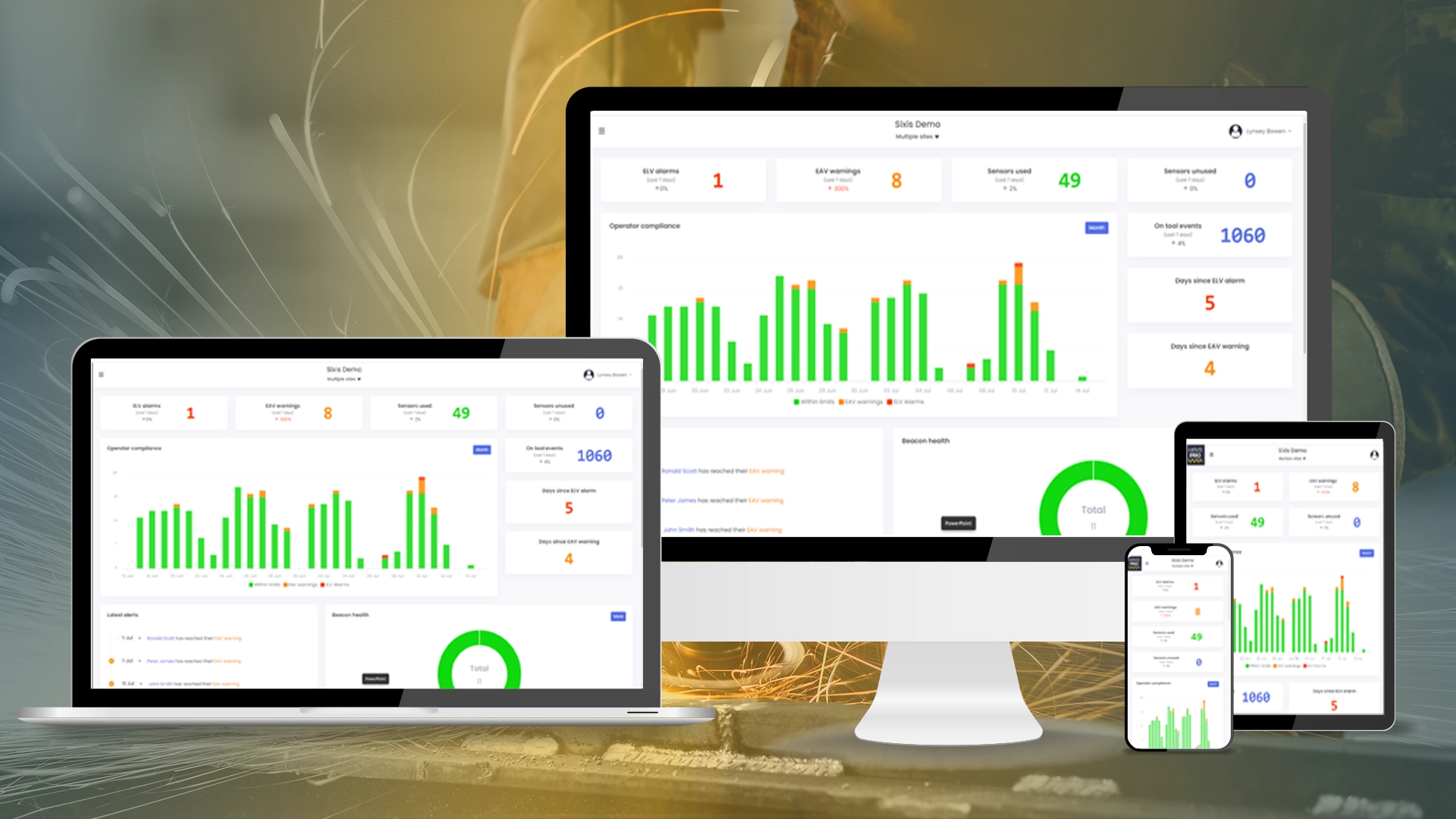

HAVSPRO is an industry-leading vibration monitoring and measuring solution that generates proactive alerts and in-depth reporting, providing unequivocal evidence in the face of litigation claims and exceeds official requirements to protect your workforce from injury.

Meeting all your vibration monitoring needs

PRO Active

HAVSPRO provides accurate alerts of accumulated vibration levels for an individual operator and customisable tailored data reports for operators, supervisors and managers so controlling breaches before they occur.

PRO Tech

HAVSPRO uses the latest technology to accurately measure Real-time measurements to help highlight tool degradation data in line with BS ISO standards with zero margins for error.

PRO Ductive

HAVSPRO takes your team beyond compliance with data tracking sufficiently sophisticated for you to plan work, initiate improvements, create accurate and dynamic risk assessments and improve targeted training schedules to minimise exposure and risk.

Download the HAVSPRO Brochure

Discover how HAVSPRO monitors vibration levels accurately and triggers alerts to protect your staff and organisation against the risks of HAVS and WBV (whole body vibration).

It monitors individual tool vibration levels and the exposure each person has to it.

HAVSPRO then collates all this data and creates customisable reports to help you prevent overexposure.

Find out everything you need to know in our brochure – simply complete the form!

#makeHAVShistory

In the UK an estimated two million employees are exposed to the risk of debilitating industrial vibration injuries caused by the repetitive strain from using hand-held tools.

By law, all businesses are required to control the risk of two conditions: Hand-Arm Vibration Syndrome (HAVS) and Whole Body Vibration (WBV). However, vibration levels all-too-often exceed safe levels if control measures are not applied and inadequate action taken which means companies have incurred fines in excess of £600,000 putting themselves at risk of significant compensation claims.

Industry GOLD Standard with HAVSPRO

The complete HAVSPRO system has been designed to address the considerable deficiencies

in existing methods for controlling vibration exposure and popular ‘tool timer’ measurement

devices, to provide a gold standard forward-thinking sophisticated yet simple solution.

The Gold Standard with HAVSPRO

The Gold Standard with HAVSPRO

- Rigidly mounted to the tools surface.

- Continuously measures and monitors vibration exposure as it is experienced by the operative.

- Provides real-time alerts BEFORE an operative is over-exposed.

- Proactive text and email alerts for EAV, 90%of ELV and 100% ELV, are sent to managers and supervisors.

- Summary reports of the reporting data is emailed to anyone who requires it so managing the risk of HAVS can convenient and proactive.

- Cloud-based reporting system that can be accessed from any internet-connected device.

- The data accumulated in the reporting system is yours property and will remain yours, even if you stop using HAVSPRO.

- The data within the reporting system can also be used to help manage occupational health reviews AND tool servicing schedules.

Protect your people and your business with one of the world’s most advanced personal vibration monitoring, measuring and reporting systems

Latest HAVS News

How HAVSPRO Makes HAVS Monitoring Easy

Effective risk assessments for vibration are essential to protect employees and ensure compliance with regulations. HAVSPRO provides precise data to identify risks, plan controls, and create accurate assessments that safeguard your business and workforce.

Social Housing Provider Fined – What the Nottingham City Homes Case Tells Us About Managing Vibration Risks

Effective risk assessments for vibration are essential to protect employees and ensure compliance with regulations. HAVSPRO provides precise data to identify risks, plan controls, and create accurate assessments that safeguard your business and workforce.

The Reality of HAVS Risk in the Latest HSE Statistics

New HSE workplace health statistics show that HAVS remains a serious risk in the workplace. Explore what the data reveals and how accurate vibration monitoring and measuring can can help businesses take proactive steps to protect workers and reduce long-term risk.