#makeHAVShistory

In the UK an estimated two million employees are exposed to the risk of debilitating industrial vibration injuries caused by the repetitive strain from using hand-held tools.

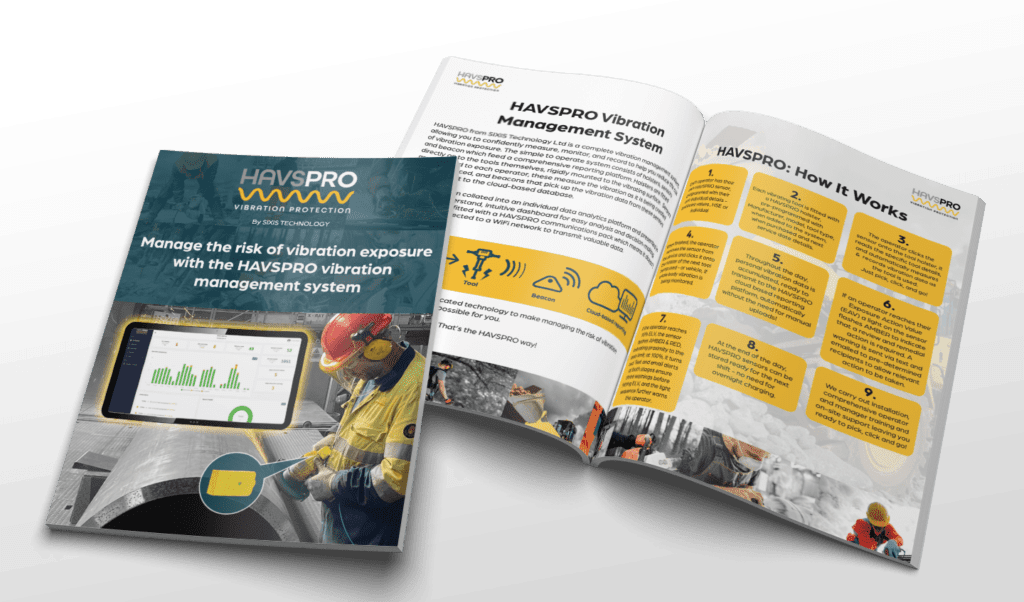

By law, all businesses are required to control the risk of two conditions: Hand-Arm Vibration Syndrome (HAVS) and Whole Body Vibration (WBV). However, vibration levels all-too-often exceed safe levels if control measures are not applied and inadequate action taken which means companies have incurred fines in excess of £600,000 putting themselves at risk of significant compensation claims.

HAVS vibration monitoring vibration monitoring system for construction

Introducing Sam Powell

In the ever-evolving landscape of businesses, the success of any organisation relies heavily on its

HAVS vibration monitoring vibration monitoring system for construction

We’re exhibiting at RailLive

When it comes to measuring and monitoring levels of Hand-Arm (HAV) and Whole Body (WBV) Vibration exposure, many businesses still rely on traditional methods such as using manufacturers’ data and adding the K factor, assuming data accuracy at the time of measurement, and then, in both cases, asking the operators how long they used the tool for, then calculating using the HSE ready reckoner.

HAVS vibration monitoring vibration monitoring system for construction

What is Whole Body Vibration (WBV) and what causes it?

When it comes to measuring and monitoring levels of Hand-Arm (HAV) and Whole Body (WBV) Vibration exposure, many businesses still rely on traditional methods such as using manufacturers’ data and adding the K factor, assuming data accuracy at the time of measurement, and then, in both cases, asking the operators how long they used the tool for, then calculating using the HSE ready reckoner.